350+ Customers

Trusted by over 350 customers worldwide across various high-tech industries.

camLine is a global leader in MES and MOM solutions, combining deep manufacturing expertise with modular, scalable software and AI innovation tailored for high-tech industries. Our experienced teams focus on local support and long-term partnerships to drive industrial innovation across diverse discrete manufacturing sectors, delivering operational intelligence that fosters manufacturing excellence and quality leadership.

Trusted by Leading Manufacturers Worldwide

Agile, efficient, and reliable software solutions built on decades of manufacturing expertise.

Since 1989, camLine has provided reliable solutions that integrate business and production processes. Our software enhances transparency, quality, and efficiency, enabling high-tech manufacturers to increase productivity, lower costs, and shorten time to market. Rooted in Bavarian quality and ISO 9001 certified, camLine supports manufacturing excellence worldwide.

Agile, efficient, and reliable software solutions built on decades of manufacturing expertise.

Since 1989, camLine has provided reliable solutions that integrate business and production processes. Our software enhances transparency, quality, and efficiency, enabling high-tech manufacturers to increase productivity, lower costs, and shorten time to market. Rooted in Bavarian quality and ISO 9001 certified, camLine supports manufacturing excellence worldwide.

350+ Customers

Trusted by over 350 customers worldwide across various high-tech industries.

40+ Countries served

Empower manufacturers achieve growth and excellence in over 40 countries globally.

35+ Years of experience

Delivering proven manufacturing software solutions with over 35 years of experience.

As your partner, we provide quality-driven manufacturing solutions that transform data into a competitive advantage for high-tech industries.

Proactively improve quality with real-time monitoring, traceability, and standardized controls.

Automate quality control and optimize production planning to achieve more with existing resources, reducing waste and rework costs.

Gain actionable insights across your supply chain, enabling root cause analysis and data-driven decision-making.

Leverage proven solutions tailored to your unique operational requirements.

Continuously advance manufacturing performance by harnessing AI and smart automation, from Lean Six Sigma enhancement to faster product innovation.

Evolve from problem-solving to collaborative innovation, supporting business growth through a committed, future-focused partnership.

We equip manufacturers with modular, scalable, and industry-focused software that drives quality improvement, operational excellence, and innovation.

Incoming Material Quality Control

Automates supplier quality and incoming material management.

Track Goods/Semi-Finished Goods

Tracks work-in-progress and ensures full material traceability.

Track and Monitor Equipment

Provides real-time equipment monitoring and maintenance management.

Maintenance Management

Maintenance software for planning and executing preventive and corrective tasks.

Advanced Statistical Process Control

Enables real-time process monitoring and statistical process control (SPC).

Recipe Management System

Centralizes recipe and parameter management for manufacturing.

Comprehensive and Scalable MES

Comprehensive MES for discrete manufacturing with open and scalable architecture.

Automated Material Handling Systems

Automates and streamlines material handling for high-volume production.

Reticle and Durables Management

Manages durables, reticles, and probe cards for efficient asset lifecycle control.

Outgoing Material Quality Control

Enhance quality assurance by automating customizable electronic Certificate of Analysis (eCoA) creation.

Statistical Trend Analysis and Reporting Gateway

Advanced trend analysis and KPI reporting across multiple manufacturing sites.

Advanced Data Analytics

Delivers advanced data analysis and Design of Experiments (DoE).

Enable precise process control, full traceability, and cleanroom compliance in wafer fabs.

Enhance yield, process integrity, and equipment coordination in assembly and packaging.

Optimize line setup, material control, and first pass yield in electronics assembly.

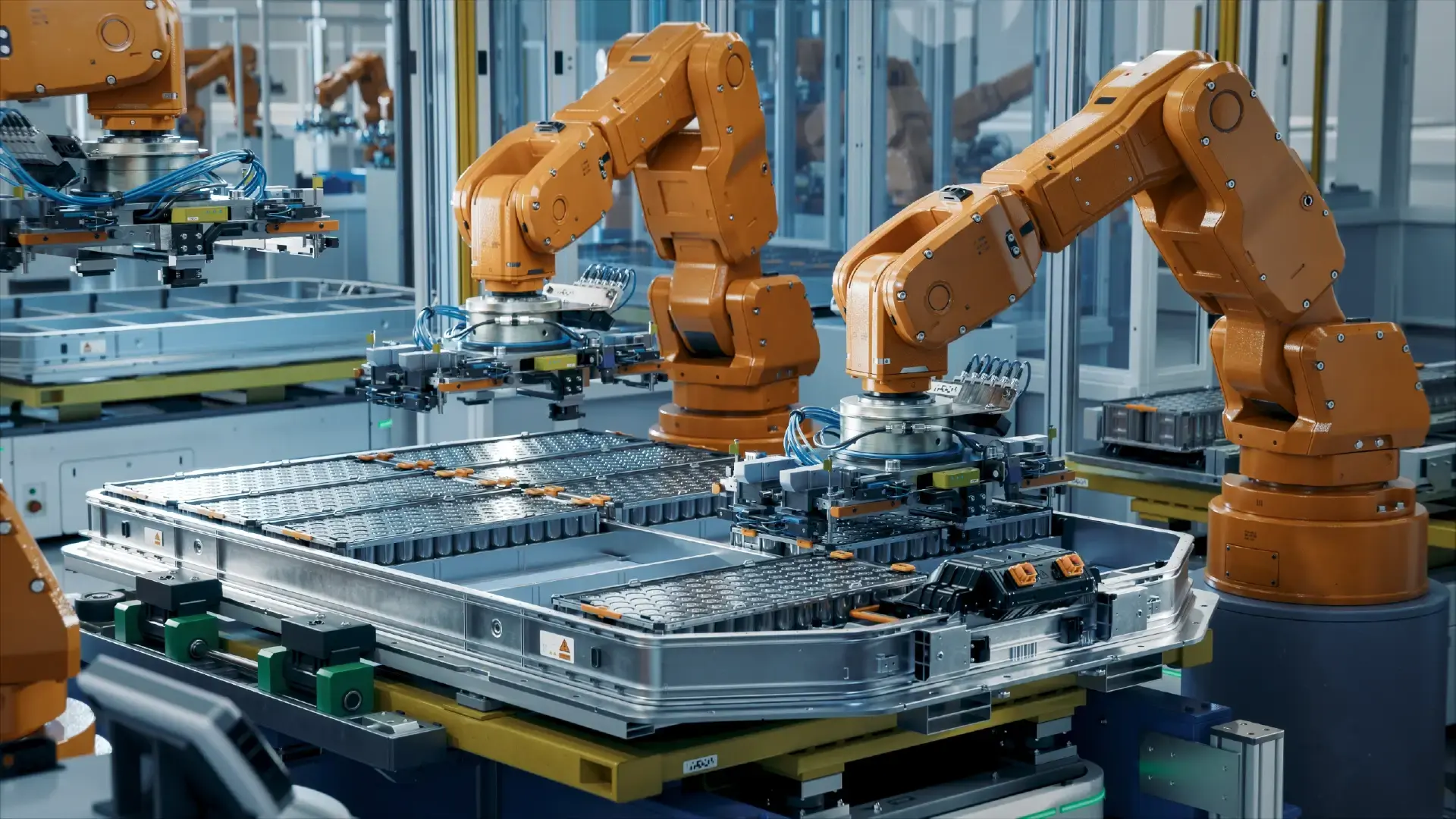

Ensure traceability, process stability, and consistent quality in battery and pack production.

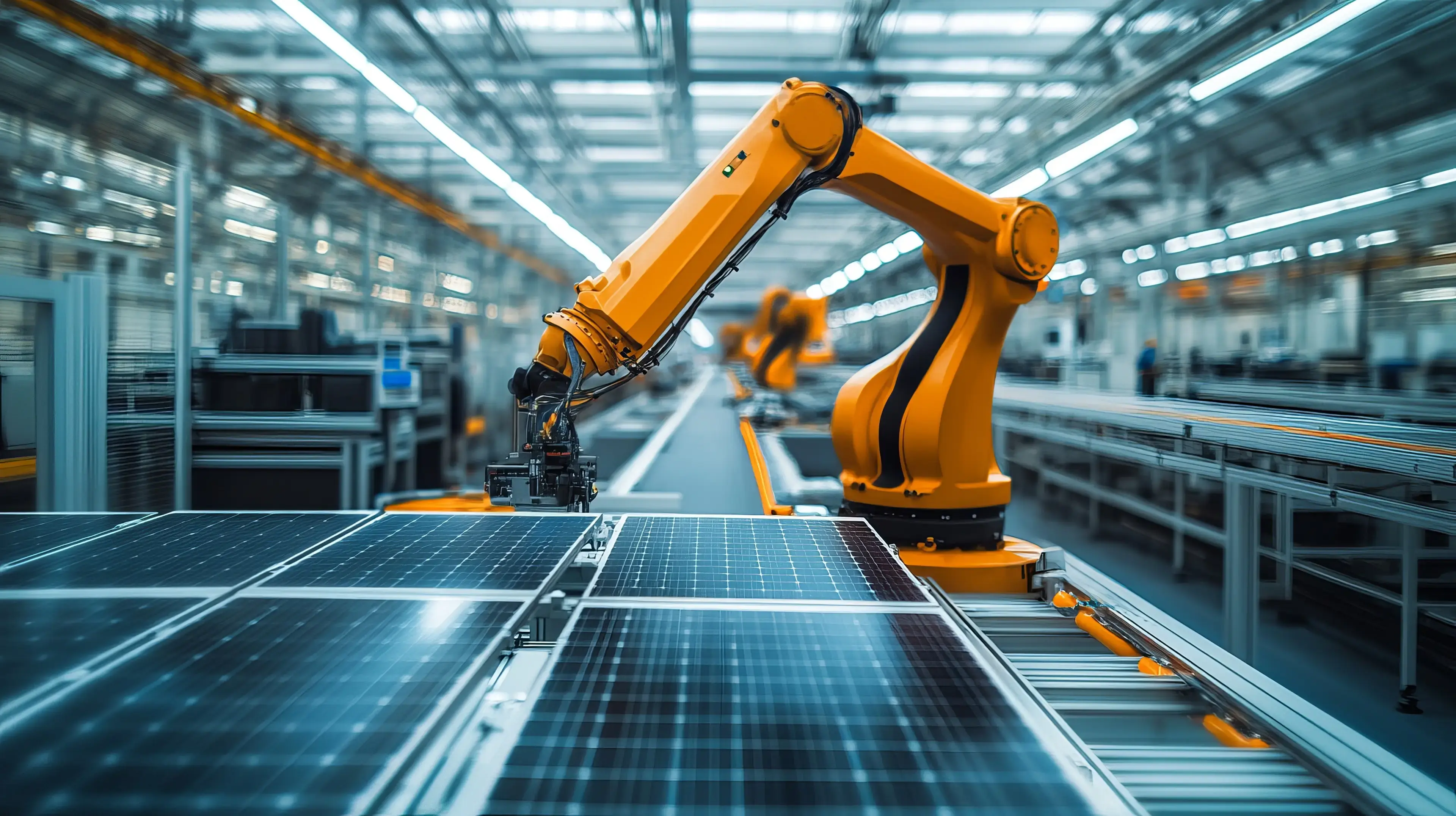

Automate production, improve quality, and enable cost-effective solar PV manufacturing.

Support compliance, end-to-end traceability, and product documentation in regulated manufacturing.

We believe successful software implementation requires more than great technology—it needs people who understand your business. Our co-development model with industry leaders ensures solutions address real-world challenges.

Our team is ready to deliver tailored solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.